Often imitated, never surpassed: When using dot adhesive – choose the original!

Here is why:

Let’s assume that a large perfumery chain is declaring a summer sale. In over 1000 stores, the campaign’s ads have to be applied to the shop windows. For time and cost efficiency, it will hardly be possible to hire professional sign makers, who will apply the ads for each store. On the other hand, it cannot be expected of all store clerks to apply the graphic themselves and achieve the same professional result a sign maker does, meaning, a smooth, perfectly applied ad. The consequences are often seen across shopping malls: Window decals with trapped air that distracts from the message. However, there is an economical, time-saving solution: the material, on which the campaign is printed, must be so easy to apply that even inexperienced first-time users can achieve professional results: This can be achieved with dot-shaped adhesive solutions.

What’s the point of using dot-shaped adhesive?

Self-adhesive printing materials with a dot-shaped adhesive are extremely easy to apply. Here is why: If air bubbles get trapped under the film during the application, they can simply be pushed out through the tunnels between the individual adhesive dots. This way, professional-looking results are extremely easy to achieve. Since dot-shaped adhesives have the above-mentioned advantages in comparison to films with a full-surface adhesive layer, many easy dot variations have appeared on the market.

easy dot® explained:

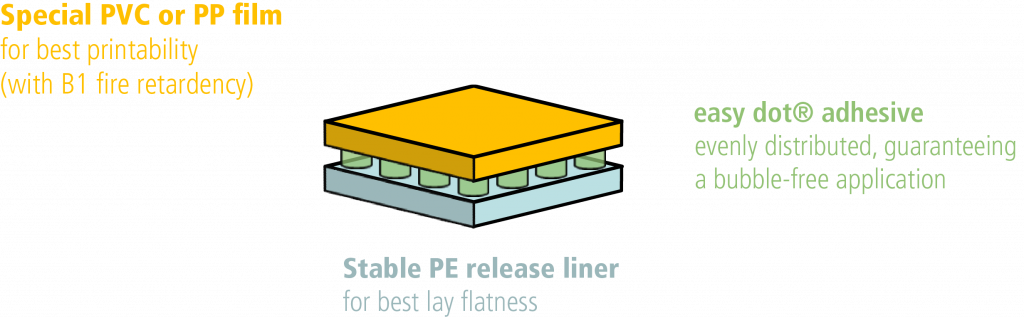

easy dot’s® top layer is a PVC film, in the middle a dot-shaped adhesive and the bottom layer is a stable PE release liner, which ensures that the material remains as flat as possible.

All original easy dot® products have evenly distributed adhesive dots. This is paramount for one simple reason: The “air release” technology – removing air bubbles simply by pushing the trapped air through the tunnels – requires a precise and even application of adhesive dots. Uneven adhesive distribution causes air to remain locked under the substrate.

When using easy dot – choose the original!

Don’t accept results like this: When choosing dot adhesive films, choose the

original easy dot®

Neschen, as the inventor of the dot technology, explains the differences between easy dot® and comparable products:

• Evenly distributed adhesive dots for air release

• The original easy dot® has a very stable PE release liner – no curling, even when exposed to moisture

• Perfect printing and plotting results

• Solvent-free adhesive

• Residue-free removal

• The new and improved easy dot® quality puts an end to the known printing problems

with latex inks (occuring with many PVC-based media)