Laminating Machines

The first Neschen laminator K600 was presented at Photokina in 1974. We are continuing this success story now.

Neschen laminators are back and better than ever before: Designed by Neschen, produced in Europe with additional benefits for our customers worldwide. The Neschen ColdLam 1650, HotLam 1650 TH, HotLam 1650 DoubleH, PhotoLam 650 and our EcoLam 1650, are our five all-rounders for every application. Not just built for our customers, but with our customers. During the design phase we intensely coordinated the design together with our customers worldwide. Our aim was to build a machine which is practical to use in their everydaywork. The designers attached much importance to having maintenance and repair executed by the customers themselves.

You want to become a reseller of NESCHEN Laminator? You need a list of our global exclusive partner of Neschen Laminator Sales & Service worldwide? Please, contact our Neschen Customer Service.

Here you can download our Neschen Laminating Machines brochure!

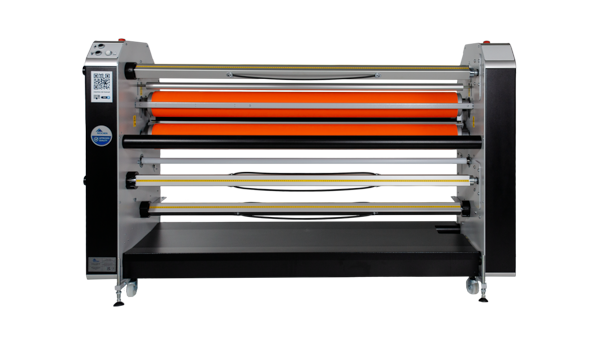

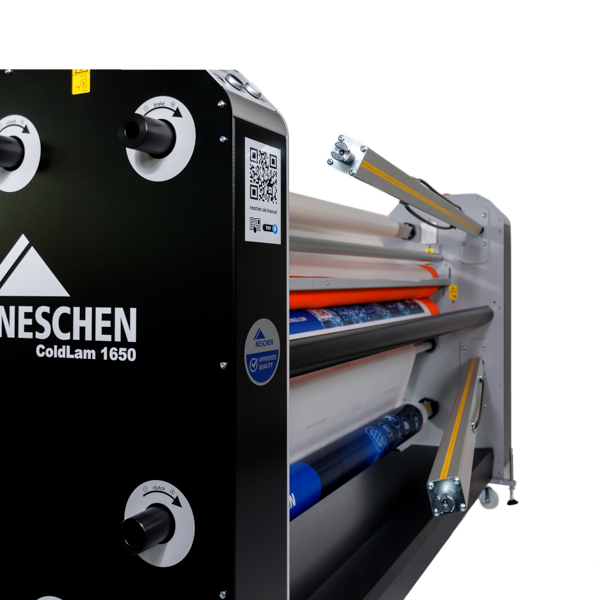

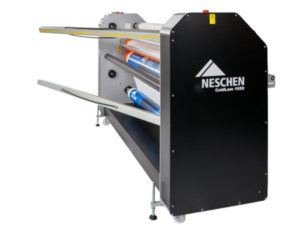

NESCHEN ColdLam 1650 SW

Developed by Neschen, made in Europe!

Description

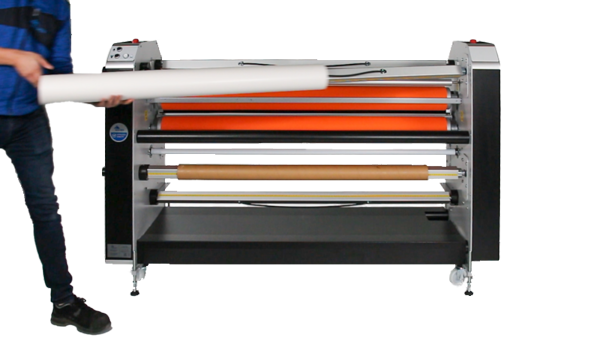

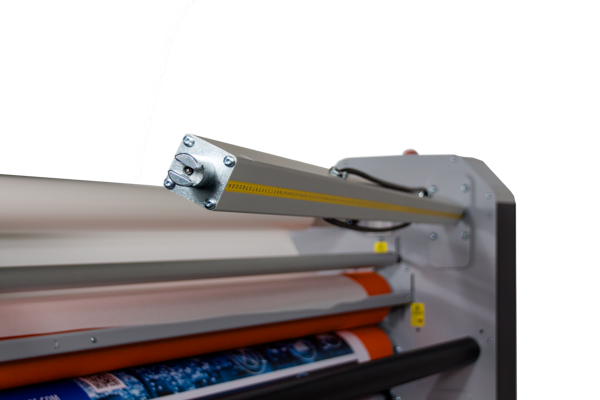

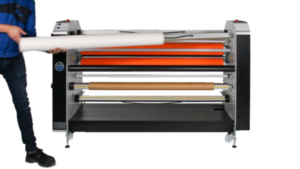

The Neschen ColdLam 1650 SW laminator is a further development of the Neschen ColdLam 1650 laminator. The Neschen ColdLam 1650 SW offers all the advantages of the Neschen ColdLam 1650 and also comes with two swing-out shafts. Handling is therefore particularly easy and gentle on people and material. The laminator is ideal for mounting and laminating prints with a width of up to 1650 mm. The machine has a heatable upper roller, which warms up cold material for processing, e.g. in winter. The laminator is suitable for processing a wide range of materials such as cardboard, photo paper and MDF boards. The feed table with integrated unwinding tray ensures easy handling of large-format media. Folding up the feed table and the control panel on the rear allow for improved control and easier work. The roll-to-roll functionality makes it easy to rewind material. The processing speed is infinitely variable up to 8 m/min via the control panel. The external brakes can be used to adjust the winding tension. Operating safety is ensured by light barriers with self-diagnosis and a removable finger guard.

A 230 V connection is required to operate the laminator.

Features

- Integrated compressor for consistent pressure

- Heat assist through heatable top roller

- Large rollers with optimum pressure distribution

- Externally located brake and clutch handles

- Swing out shafts

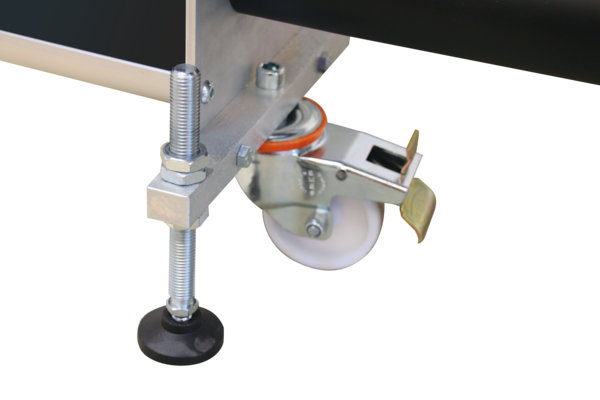

- Sturdy adjustable feet for safe working

- Durable and robust construction

- Safety foot pedal

- Levelling feet

Größen

| 6046466 | ColdLam 1650 SW | 1650 mm working width |

| 6040877 | 76 mm > 150 mm | industrial core adapter (Set = 2 pcs.) |

| 6040476 | Cutting system | |

| 6045674 | Set | Infeed table add-on pack |

related products